5 Mistakes Customers Make When Ordering CNC Parts (and How to Avoid Them)

Ordering CNC parts seems simple – you send a drawing and receive a finished product. But in practice, small mistakes at the beginning can lead to delays, additional costs, or even unusable parts.

In this article, we will look at the 5 most common mistakes customers make and show you how to easily avoid them.

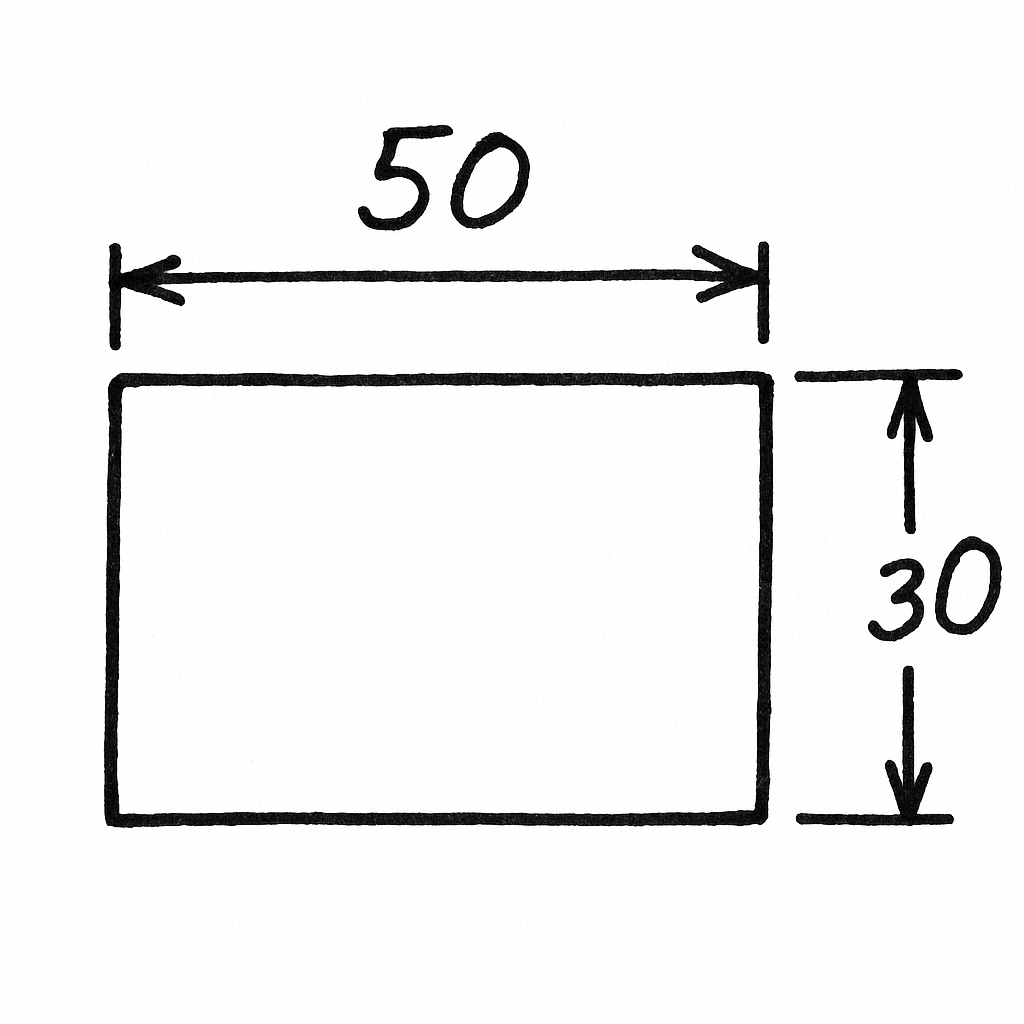

Lack of a complete technical drawing or 3D model

Problem:

Many customers send incomplete information – a hand-drawn sketch or a drawing without all dimensions and tolerances. This makes production difficult and requires additional time for clarification.

Solution:

Send complete CAD file (.STEP, .IGES, .DXF) or detailed PDF drawing.

Include tolerances, materials and surface treatment.

If you don't have a ready file - we can create a 3D model based on your idea.

Unclear material choice

Problem:

“I want it made of metal” – this is not enough. Different metals and plastics have different properties and cost. An inappropriate choice can lead to breakage, distortion or rapid wear.

Solution:

Define for what environment the part will be used (temperature, humidity, mechanical load).

Ask for a recommendation – we can often suggest a better or more economical material.

Examples:

Aluminum 6061 – lightweight and corrosion resistant.

POM (delrin) – excellent for low-friction mechanical elements.

Прекалено сложна геометрия без реална нужда

Problem:

Понякога детайлите са проектирани с ненужни сложни форми, които оскъпяват или забавят производството.

Solution:

Опростете дизайна, ако функцията го позволява.

Консултирайте се с нас още на етап проектиране – можем да предложим по-производими решения.

Използвайте принципа „Design for Manufacturing“ – детайли, които се произвеждат лесно, са по-евтини и по-бързи за изработка

Lack of clear quantity and deadlines

Problem:

“I’ll need a few pieces… soon.” – this is too vague and makes production planning difficult.

Solution:

Define exact quantity и deadline even when asked.

If you are not sure about the quantities – ask for a quote for different series (for example, 10, 50 and 100 pcs.).

This allows for a better price and ensures that you receive the parts on time.

Skipping quality control upon receipt

Problem:

Some customers accept the shipment without inspection and only later discover that there are discrepancies.

Solution:

Check upon receipt the main dimensions and visual condition.

If necessary – ask measurement protocol or a certificate for the material.

With us, all details go through a final check, but it is good for the client to also check

Conclusion

Avoiding these 5 mistakes can save time, money and nerves both the customer and the manufacturer.

When ordering CNC parts, the more complete and clear the information, the faster and more accurately you will receive the desired result.

If you have a project and would like to receive a free consultation on design optimization or material selection – contact us.